Over the years we have undertaken various LabVIEW based projects for various industries, premium institutes and research institutes across India and the globe with a success rate of 100%.

Some of our systems have been successfully deployed in Kazakhstan, Germany and US.

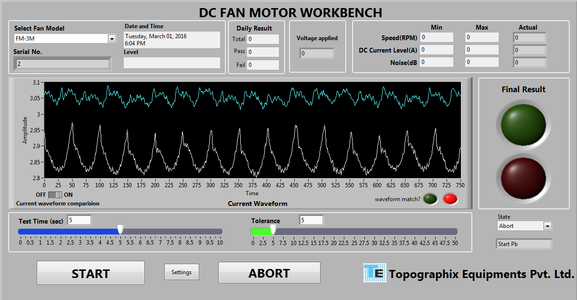

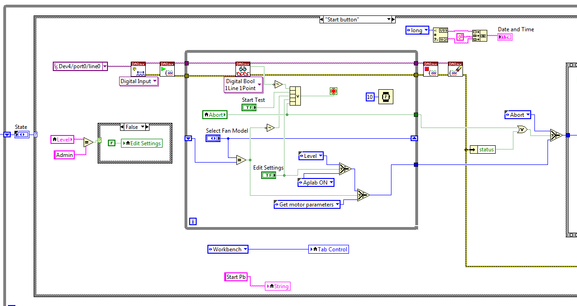

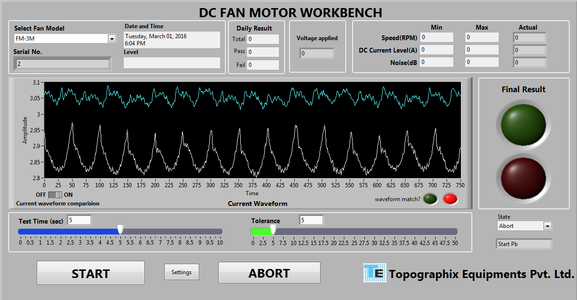

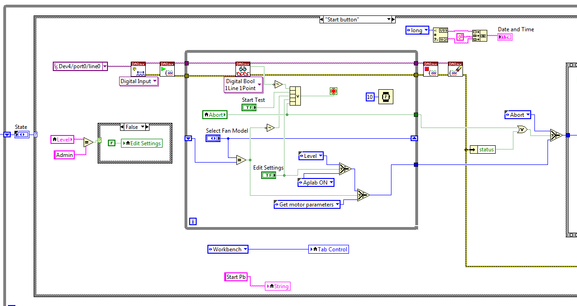

project name : DC Fan Motor TestBench

client name : Kinetic Electric

The client manufactures DC Motors for exhaust and other types of fans for industrial and automobile applications for companies like Renault, Nissan, Mahindra, Piaggo, Hero and TATA.

DC Motor Testbench is deployed on their various assembly lines. In this system the DC motor has to be tested for various parameters such as voltage, current drawn, noise, speed as well as current waveform. Go-No Go decision is taken based on the above parameters and in depth signal analysis of the captured current waveform.

Testbench also has a unique bar-code generation system with data logging and storage for historic analysis.

project name : Vibration Monitoring System

client name : KEM

Apart from electrical parameters of a motor, it is essential in automotive industry for the motors to be as less vibrating as possible so that the customers can enjoy a smooth ride. Herculean task of monitoring these vibrations coming out of a motor during production was previously done using hand held vibration meters and was subject to human errors. The newly developed automated system by Topographix reduces the human intervention on to loading and unloading on the motors on the fixture. Rest everything is taken care of by the system. Pneumatic controller 5 single axis sensor and one tri-axial sensor give comprehensive vibration data of the motor at various points on the motor as well as the car. Data is safely stored in a database for recollection and traceability is provided by a unique QR code generated at the end of every cycle.

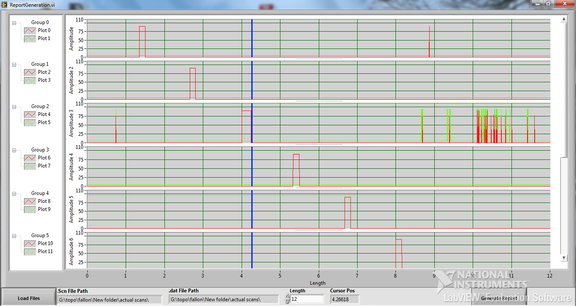

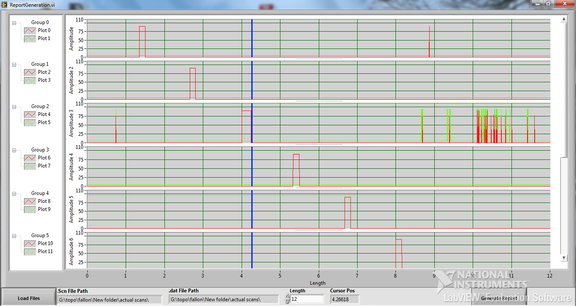

project name : Pipe Leak Detection System

client name : Fallon Ultrasonics India Pvt. Ltd.

The actual deployment of this system is in Kazakhstan. The system detects minute defects in pipe via ultrasonic sensors. Each flaw is shown on the graph with its exact location.

Data for all the pipes is stored in a database and word/pdf report is generated after every cycle.

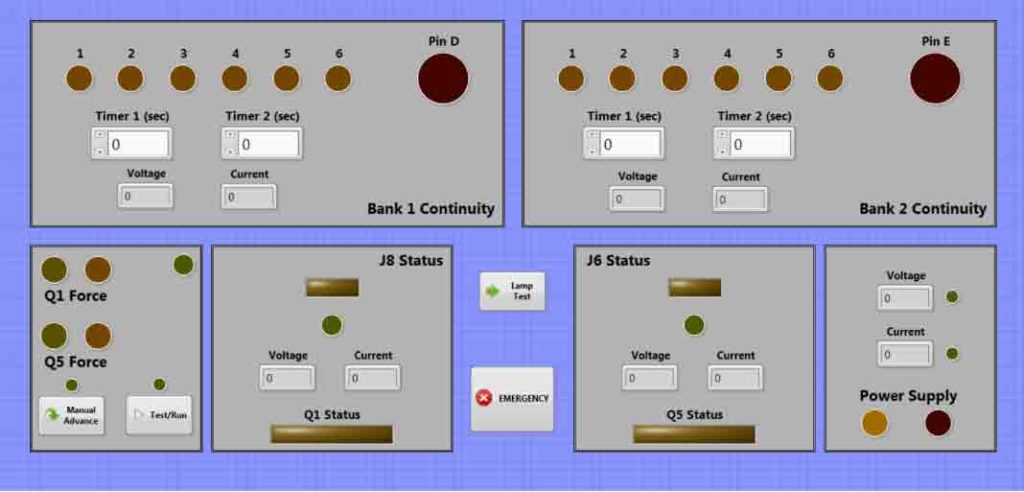

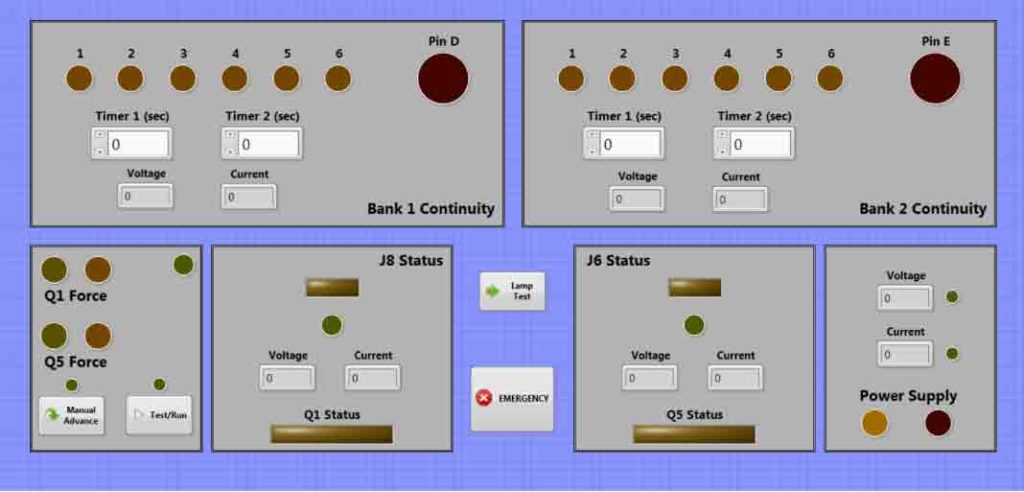

project name : Aviation Parts Test System

client name : Qualified technologies, USA

This labview based system is designed to test the dashboard of commercial aircrafts. Our US based client manufactures dashboard electronics for commercial aircrafts and this labview based system tests the electronics such as timers before they can be dispatched. This automated test workbench now takes only a few mins saving hours of manual testing. With possibility of 100% trace-ability, the system is scalable and customizable as well.

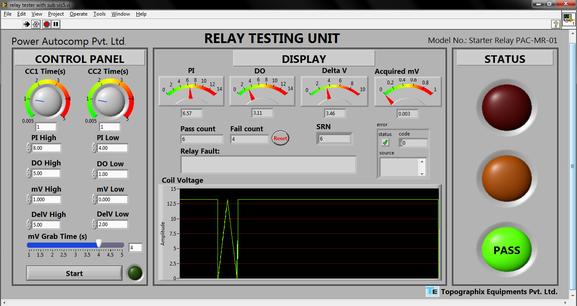

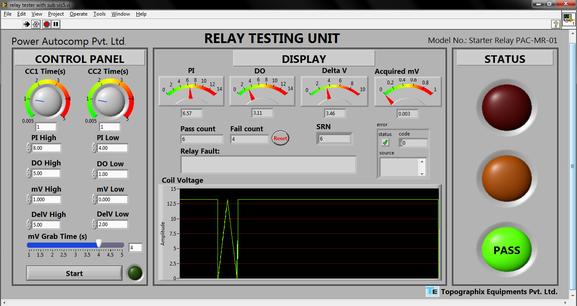

project name : Relay Testing unit

client name : Power Autocomp Pvt. Ltd.

The client manufactures starter relays for companies like Honda, Suzuki, Hero, Bajaj and TVS. There are various tests to be carried out on a relay before dispatch such as Pull-In voltage, Drop-out voltage, coil resistance, and contact resistance.

This LabVIEW based system can test a single relay in less than 2.5 seconds as to their previous systems which required 6-7 secs. Their production increased by 200%

project name : Beam Viewer

client name : BARC, Mumbai

The system is actually deployed at RRCAT, Indore.

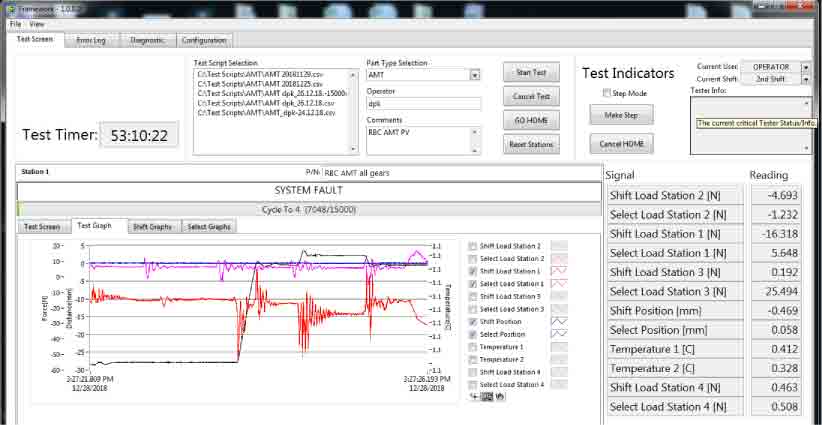

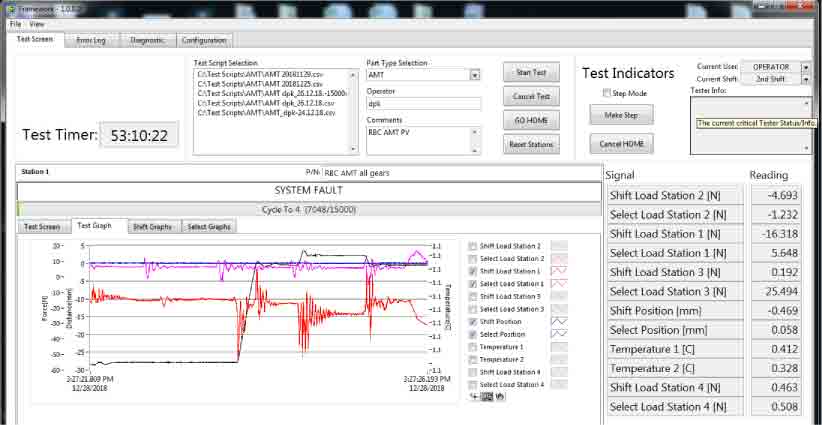

project name : Automobile Gear Test System

client name : Dura Auto

This labview based system is designed to simulate the life cycle of a manual or automatic gear systems that fit in cars like Jaguar, Land Rover, Ford, Renault, etc. Highly complex algorithm is back by 18 different Load cells, 15 other sensors such as LVDTs, Rotary potentimeters, temperature sensors, FPGA devices, CRIO chasis and Galil Motion controller for accurate measurement and control. The client is able to simulate lifecycle of a gear box and its components in the matter of months.

project name : DC Fan Motor TestBench

client name : Kinetic Electric

The client manufactures DC Motors for exhaust and other types of fans for industrial and automobile applications for companies like Renault, Nissan, Mahindra, Piaggo, Hero and TATA.

DC Motor Testbench is deployed on their various assembly lines. In this system the DC motor has to be tested for various parameters such as voltage, current drawn, noise, speed as well as current waveform. Go-No Go decision is taken based on the above parameters and in depth signal analysis of the captured current waveform.

Testbench also has a unique bar-code generation system with data logging and storage for historic analysis.

project name : Vibration Monitoring System

client name : KEM

Apart from electrical parameters of a motor, it is essential in automotive industry for the motors to be as less vibrating as possible so that the customers can enjoy a smooth ride. Herculean task of monitoring these vibrations coming out of a motor during production was previously done using hand held vibration meters and was subject to human errors. The newly developed automated system by Topographix reduces the human intervention on to loading and unloading on the motors on the fixture. Rest everything is taken care of by the system. Pneumatic controller 5 single axis sensor and one tri-axial sensor give comprehensive vibration data of the motor at various points on the motor as well as the car. Data is safely stored in a database for recollection and traceability is provided by a unique QR code generated at the end of every cycle.

project name : Pipe Leak Detection System

client name : Fallon Ultrasonics India Pvt. Ltd.

The actual deployment of this system is in Kazakhstan. The system detects minute defects in pipe via ultrasonic sensors. Each flaw is shown on the graph with its exact location.

Data for all the pipes is stored in a database and word/pdf report is generated after every cycle.

project name : Aviation Parts Test System

client name : Qualified technologies, USA

This labview based system is designed to test the dashboard of commercial aircrafts. Our US based client manufactures dashboard electronics for commercial aircrafts and this labview based system tests the electronics such as timers before they can be dispatched. This automated test workbench now takes only a few mins saving hours of manual testing. With possibility of 100% trace-ability, the system is scalable and customizable as well.

project name : Relay Testing unit

client name : Power Autocomp Pvt. Ltd.

The client manufactures starter relays for companies like Honda, Suzuki, Hero, Bajaj and TVS. There are various tests to be carried out on a relay before dispatch such as Pull-In voltage, Drop-out voltage, coil resistance, and contact resistance.

This LabVIEW based system can test a single relay in less than 2.5 seconds as to their previous systems which required 6-7 secs. Their production increased by 200%

project name : Beam Viewer

client name : BARC, Mumbai

The system is actually deployed at RRCAT, Indore.

project name : Automobile Gear Test System

client name : Dura Auto

This labview based system is designed to simulate the life cycle of a manual or automatic gear systems that fit in cars like Jaguar, Land Rover, Ford, Renault, etc. Highly complex algorithm is back by 18 different Load cells, 15 other sensors such as LVDTs, Rotary potentimeters, temperature sensors, FPGA devices, CRIO chasis and Galil Motion controller for accurate measurement and control. The client is able to simulate lifecycle of a gear box and its components in the matter of months.

We, Topographix Equipments Pvt. Ltd. are in operation since year 2000.

We’re committed to providing you with top notch technical solutions and support. We approach every client with a focus on integrity, advocacy, and understanding.

Our technical team has a well-deserved reputation of excellence in providing smart, creative and cost-effective solutions for our clients.